Screw Documentation

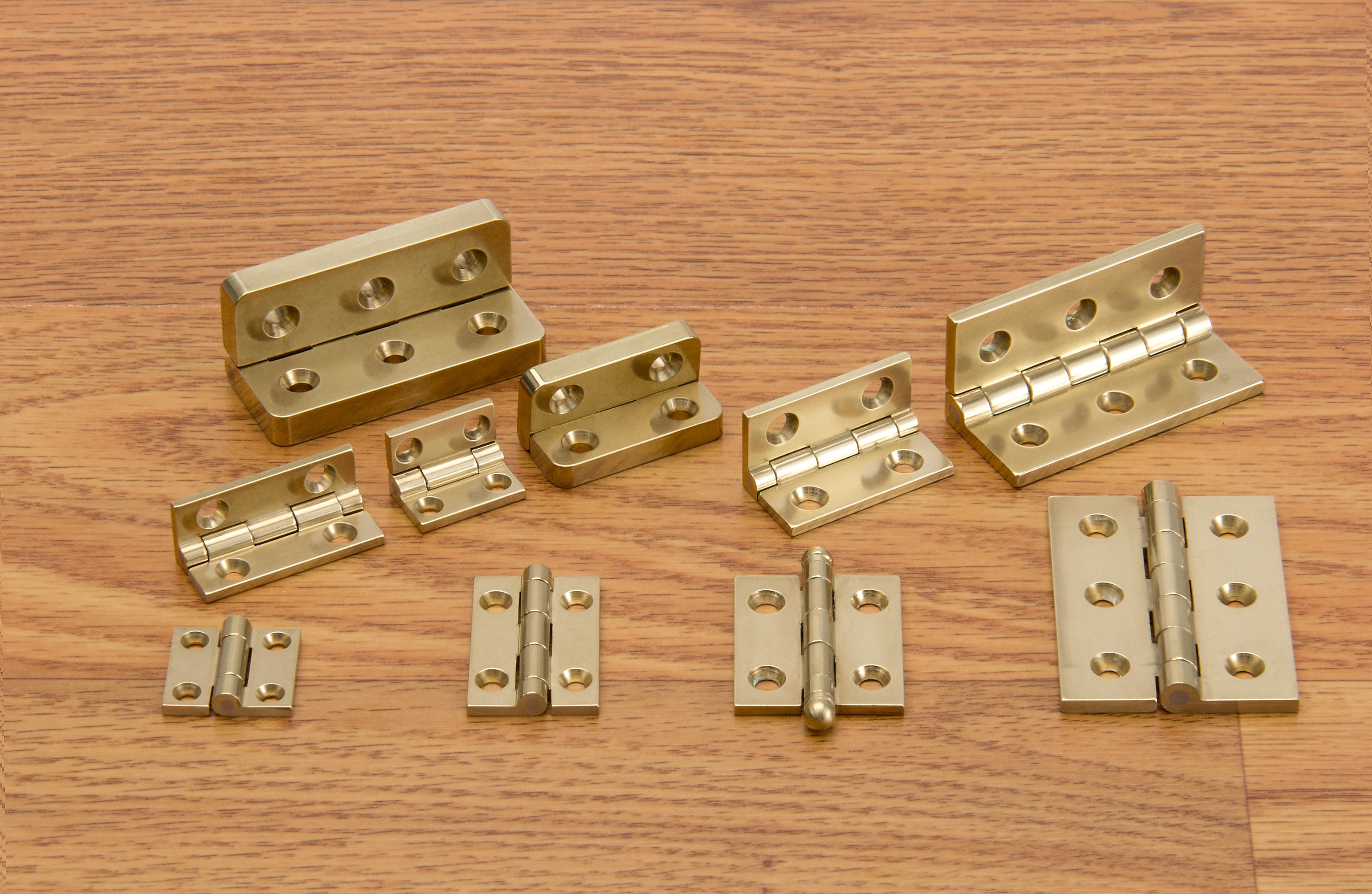

At Brusso, we pride ourselves on the high-quality brass finishes we offer. To ensure a uniform finish, all our brass hardware ships with solid brass screws. We don't use plated or coated screws because we want the brass to age uniformly over time. We've used the same source for our brass screws for many years and do not shop around to save costs.

Benefits of Brass Screws

Using solid brass screws has many benefits, including a consistent and high-quality finish. However, due to the soft properties of brass and the small screw sizes, breakage is always a possibility.

Risks of Breakage

Even with the best practices, screw breakage can occur. It's a frustrating experience that happens to woodworkers of all levels. But don't worry, a broken screw is salvageable, and your project can continue.

Here is a step-by-step guide to screw removal:

-

Relieve the Area: Use a chisel, Dremel, or drill bit to make space around the broken screw. Keep the area small so it can be hidden by the hinge.

-

Use Sharp Tools: Use sharp diagonal cutting pliers to grab the screw remnants and rotate counter-clockwise until free.

-

Evaluate the Hole: Sometimes, wood glue and a new screw will suffice. You can also use wood filler or putty in the screw hole. Ensure the new mortise surface allows your hinge to sit flat.

Screw Installation

The best way to prevent screw breakage is to take the appropriate steps during installation. Here's some simple steps we recommend:

- Read Install Instructions: Always read the install instructions linked from our product pages.

- Drill Pilot Holes: Drill a pilot hole slightly smaller than the screw body. Pilot hole sizes vary for hard and soft woods, and the hole should be the same length as the screw.

- Use the Pilot Screw: For our smaller sized products we include a steel pilot screw. After drilling your hole use this screw to make room for your final screws.

- Wax Application: Before installing screws, apply wax to ease the force on the screw.

-

Finish Up: Use a manual screwdriver with an appropriately sized head and a light touch. Avoid using an electric drill.

Screw Wax Recommendation

We sell and recommend Screw Wax brand wax, made in the USA with bee's wax. Our customers find it superior to bar soap or lip balm.

FAQs

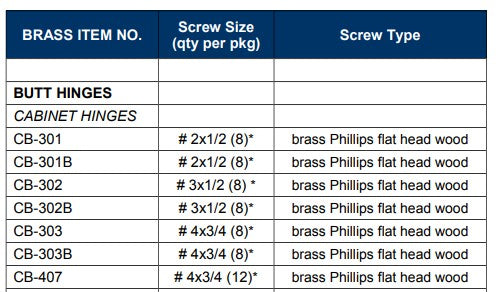

Q: Where can I find a replacement for a screw that was included with a Brusso Hardware part?

A: Check our screw reference chart to see what size screw your part shipped with. You can purchase a replacement wood screw from your local hardware or woodworking store. If you can't find one, let us know, and we'll arrange a replacement. We recommend using a solid brass screw to ensure even aging with your hinge.

Q: The screw that shipped with my part is too long for my project. Where can I find a shorter screw?

A: We recommend using the screws that ship with your part as is. If you need a different size, refer to our screw reference chart for various screw sizes. The first number indicates the screw size (#2, #4, #6), and the second number is its length. As long as you match the first number, the screw will fit properly. If the screw is too long, you can purchase a shorter one or grind down the length. If using a shorter screw, consider applying glue or adhesive to the pilot hole to ensure it stays in place.

GET MORE

The newsletter is your go to place for the latest other resources and more from our video vault.